|

DRILLING:

Reservoir development plans call for 11 horizontal oil producers, 6 water injectors and 2 wells that will produce injection water. Produced water from oil processing will also be reinjected into the reservoir to provide aquifer support during production. Water based drilling mud will be used whenever possible, while oil based drilling fluid will be re-circulated and reinjected.

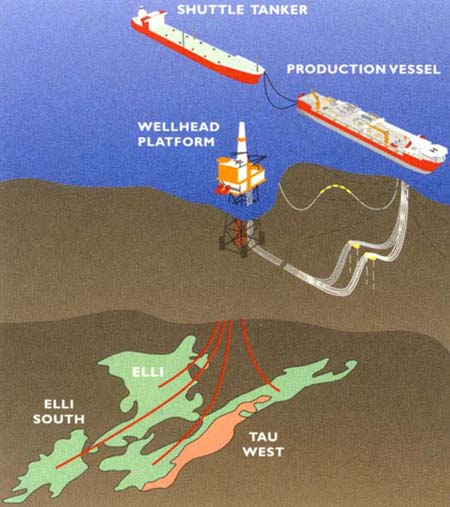

The wells will have a measured depth of up to 7000m. FIELD DEVELOPMENT: Jotun will be developed by a wellhead platform tied back to a floating production vessel. Oil will be exported by shuttle tanker. |

|

TOPSIDES: The wellhead platform consists of an integrated deck with utilities, wellhead systems, helideck, support systems and complete drilling facilities with derrick and mud facilities. Herema Tonsberg was the main contractor in consortium with ABB Offshore Technology. The company carried out deck construction and WHP integration. The Platform deck engineering and installation of electrical and instrumentation systems, along with offshore hookup, was carried out by ABB in Oslo. |

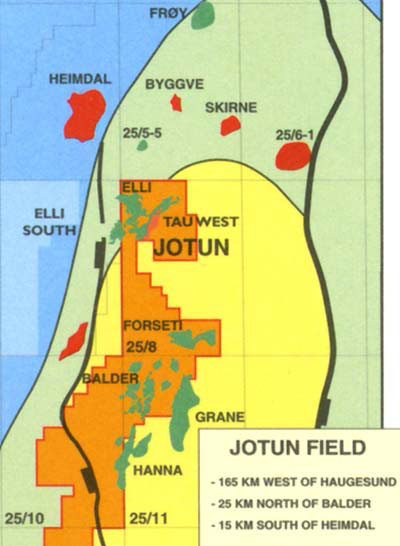

| JOTUN is located on the Utsira High (Northsea) between the Balder and Heimdal fields approximately 200 km west of Stavanger -Norway.

Average water depth in the field area is 126 m. Geologically, Jotun consists of the Elli, Elli South and Tau West, structures. The 4km by 5km Jotun RESERVOIR: lies in a Paleocene basin. The oil/water contact has been located at 2,091m below the seabed. The oil column thickness in exploration wells range from 18 to 46 m. Recoverable reserves are estimated at approximately.200 million barrels of oil (32 million m3) and 1.8 billion m3 of gas. Specific gravity of crude is 38 deg API. Reservoir pressure is 200 bar and reservoir temperature 82 deg C. |

|

PRODUCTION VESSEL: The production storage vessel is 233m in length and 42m in width. The topsides construction was carried out at the Kvaerner Rosenberg yard at Stavanger, while the hull engineering and construction was carried out by the Kvaerner Masa Yards in Finland. The production vessel hull has double sides and bottom. The topsides contains processing, living quarters, power generation, utility systems, safety and emergency systems, support communication, control, instrumentation and electrical systems. The flare will be placed aft. |

|

|

|||

Aug '98 - Oct '99

ESSO NORWAY - HONEYWELL NORWAY - Safety System Commissioning Engineer For both the ESSO JOTUN projects on the North Sea, the WellHead Platform and the FPSO, LOGIC IMPLEMENT was involved to determine parts of the philosophy with client for F&G systems and for ESD system.

Updating and finallising the Configuration on both the PLC and DCS (GUS station) and Construction supervision for the panels and interconnections, were part of the activities. However, the main activity was the Commissioning assitance with ABB on the Wellhead and with Kvaerner on the FPSO. The emanated Punchlist from these activities were handled (=solved) and assistance was rendered at Start-up of the Fire & Gas and the ESD Safety Systems at the ABB and Kvaerner commissioning teams. All activities, with related systems, for the ESSO JOTUN (WHP & FPSO) project were as well at On-shore, in Tonsberg and Stavanger Norway mainland, as at Off-shore location. More information about this project can be found at:

http://www.offshore-technology.com/projects/jotun/index.html |

The company logo might refer to expierence related |

||||